Matt's Awesome Stuff

Hope Tree

Last updated: 15Apr2012

This piece is a hybrid of two different ideas. In the spring of 2010 I had come up with an idea for a wedding gift for a bride-to-be friend of mine. I figured the reason most couples break up is lack of communication, so I thought a sensitive and functional wedding gift would be something that would bring the two together for a few minutes every day. I theorized making a waist-high tree out of stainless steel wire, where each branch ended in a tiny loop. On the ground would be "leaves", in this case loose rings of various colors which the couple would have instructions to add to the tree. One ring each, together, every day for the rest of their lives. The tree would age in reverse, gathering up leaves from the ground. Growing and flourishing every day along with their marriage. Aww. So corny.

I bought some stainless for the task and then realized how difficult it would be to twist it into a tree. I also thought, who would want a three foot tall fake tree sitting in their house all day? Where would they put it? So I abandoned that gift idea and gave them something lame and uninspired instead.

Several months later in the fall, I had been working on some microwave salvaging projects where I hadn't yet discovered a use for the 2000 feet of 28awg wire on the secondary. I thought back to the tree idea and had some inspiration from a memory of a condemned tree that was growing out the side of an eroding cliff. In soft copper and 1/4 the size, this project seemed more feasible.

A condemned tree seemed rather morbid for my mood at the time, so I thought of it in a more positive light. The tree only appeared to be condemned, by circumstance. But in fact not only survived its situation, it took advantage of it and thrived despite it. All the other trees had to compete with each other for their rays of sunlight, but this tree reaching out over the gorge had access to far more.

I thought it a good metaphor for human perseverance in the face of challenges and a solution for when times are tough. Dig down into what you've got and don't let go. When it was done I gave it away (not to the bride, to a different girl). She'd had a rather rough year, and a rough life overall, and I thought she would appreciate it and make use of the metaphor.

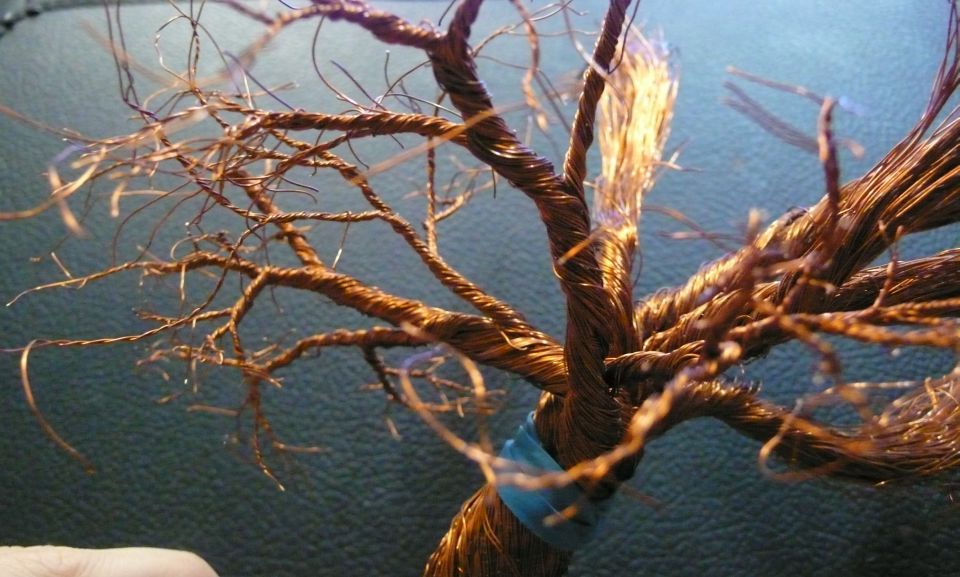

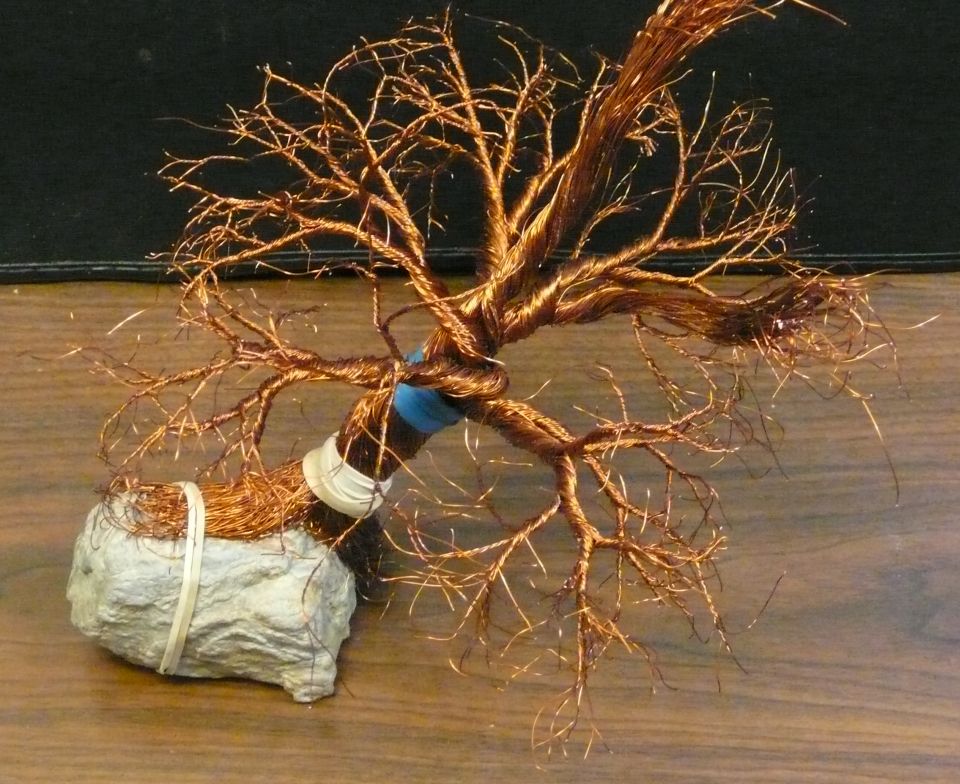

It was hard to take pictures of. There's so much detail that without stereo vision and depth of focus it just seems like a busy blur. A shame it doesn't appear on a screen like it does in person. Here's some glamor shots, construction details to follow.

Construction Details

First I started out with a microwave oven transformer secondary coil. 2000 turns of 28awg wire. Then I cut it in half and spent an hour or so separating most of the wires from each other. I didn't do this enough, so there are sections where the wires are clumped together with varnish and don't twist easily.

Then I halfheartedly twisted them and bundled them with rubber bands so they wouldn't move on me, and roughly separated the "trunk" into even-but-not-too-evenly sized "limbs".

Then, the bending, twisting and separating. I'm a left-brained structural type person, so building something random and chaotic and non-symmetrical like a tree was challenging. I did not want it looking phony and man-made.

I constantly struggled to either over-think or not think at all, and avoid normal-think. Branch coverage needed to be random, but not too random. Splits had to occur regularly, but not too regularly. Branches had to expand to fill empty space, but not perfectly. I had to keep an overall limit in the shape of the tree canopy, since the trunk was leaning at an angle but the branches would be reaching mostly horizontal for coverage.

By this point several days had passed and I was getting weary. My fingertips looked like velcro from being cut and twisted so much. I'd done about 800 wires so far, and every single one of them had to end on its own in a different direction. Thousands and thousands of twists along the way.

Also at this point, there was no way to set the tree down to take a break, so I rubber banded the roots to the rock. Progress slowed since I couldn't just twist the tree any which way to get better angles, and I had to plan a bit more to not collide with previous limbs.

One of the unexpected challenges is that the limbs only stayed twisted in the original positions. That is, if I wanted to bend a branch differently later on, it would loosen up and look sloppy and there was no way to fix it. So I had to get it all right the first time. Some foresight was useful. During the construction process I had no idea if it would turn out or not so the building was stressful. Turned out well in the end.

Roots were particularly challenging. They each had to follow the contours of the rock, but meanwhile I had to support the whole thing in one hand while twisting with the other. Getting them to stick was also challenging, I experimented with several bottles of superglue, some contact cement, weldbond, and some gorilla glue, E6000, silicone and GOOP where there were gaps to fill. Extra adhesive looked sloppy so I had to get just the right amount on the backs of the wires. Sometimes I sanded the backs of the wires so the adhesive would stick better. Lost a lot of fingertip skin holding wires down tight until the glue dried.

The last step was to anchor the tree to the rock. I spent a day hunting through the local riverbed and hauling 30 pounds of rocks home until I found the perfect one.

Since most of the tree roots should have gone "underground" into the cliff rather than being splayed out on the surface, I kept about half the strands from the middle loose. I tried drilling into the rock with a concrete bit with mild success. I followed up with a Dremel and diamond abrasive to expand the cavity into an internal cone.

I cut these shorter, filled the hole in the rock with JB Weld steel epoxy, set the hidden roots into the hole, epoxy rushing out into the hidden base of the tree, held it still for 20 minutes and it seemed to hold great.

I got a bit out of order there. First I twisted the roots to match the rock, then I inserted the trunk into the epoxy-filled hole, then I superglued all the roots down.

Overall, it was far more complicated than I imagined it would be at the start. The worst part was 3/4 of the way through when I wasn't sure if the idea was going to work and I was burning out. I'm glad I kept going, it's one of my favorite pieces though I'll probably never make another. I found a different use for the old MOT secondaries anyway.